Understanding Ecoating in the West Midlands

Ecoating, commonly referred to as electrocoating or E-coat, is an advanced method of applying a protective layer of paint through an electrochemical process. It has emerged as a vital technique in various industries, particularly in the West Midlands, known for its manufacturing prowess. This article examines the significance of ecoating, delving into its advantages, environmental impacts, key industry players, processes, applications, and practical advice for organizations considering ecoating services. If you’re exploring high-quality ecoating solutions, there are efficient options available in the ecoating west midlands sector.

What is Ecoating?

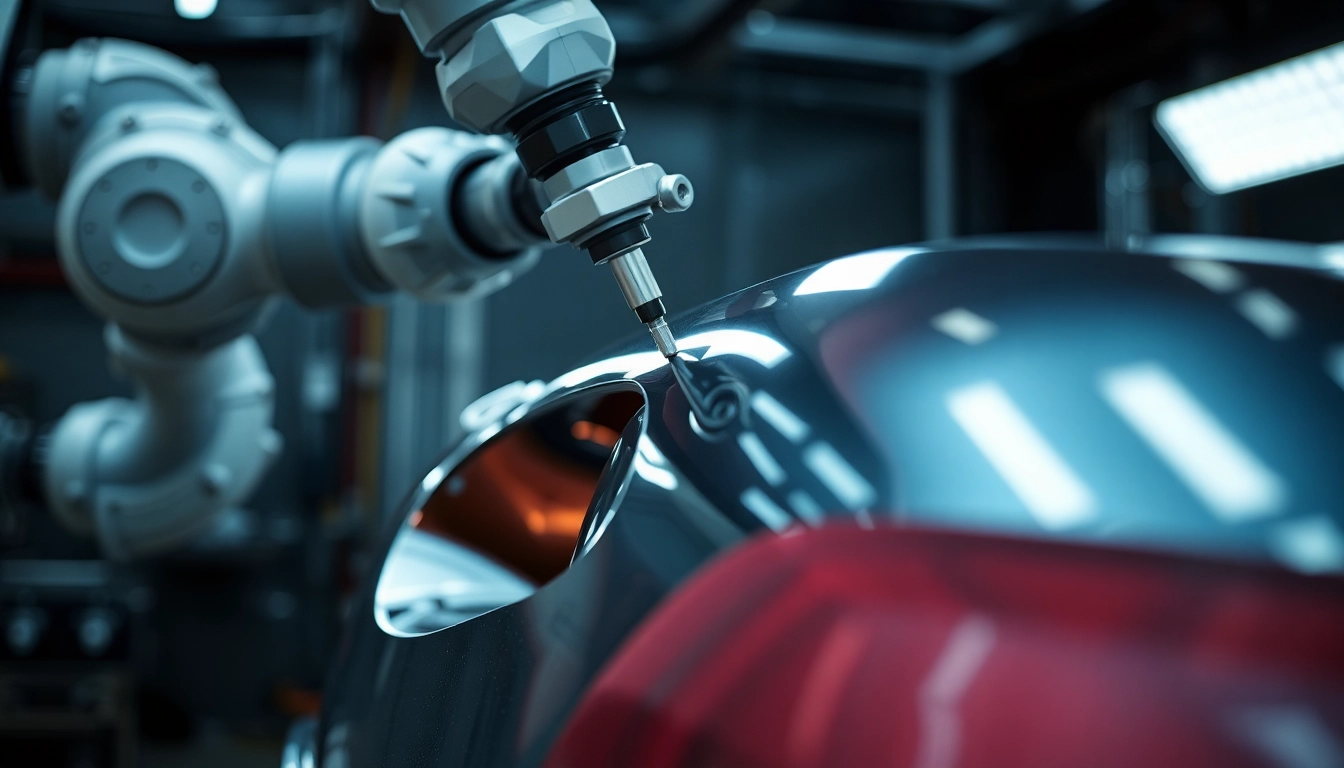

Ecoating is a method utilized for coating various components, primarily those made from metal. The process incorporates the use of electrically charged particles in a water-based solution to uniformly coat the surface of the substrate. This not only ensures an even finish but also provides excellent corrosion resistance.

Essentially, the ecoating process begins with cleaning the substrates to remove any contaminants that could affect adhesion. Next, the components are immersed in an electrocoating bath where a direct current is applied, causing paint particles to adhere to the surface. This method is particularly advantageous for complex shapes and recessed areas, ensuring comprehensive coverage that manual painting methods often miss.

Advantages of Ecoating in Manufacturing

The benefits of ecoating extend beyond mere aesthetic considerations. The technology offers numerous advantages that are pivotal in a competitive manufacturing landscape:

- Uniform Application: Ecoating provides a consistent and even finish, essential for quality control in manufacturing.

- Environmental Compliance: The use of eco-friendly, water-based paints makes this method less harmful to the environment compared to solvent-based alternatives.

- Corrosion Resistance: Components treated with ecoating are far better protected against rust and corrosion, enhancing product lifespan.

- Cost Efficiency: Although initial setup costs can be high, the long-term benefits of reduced waste and increased durability often justify the investment.

- Reduction in Labor Costs: Automation within the ecoating process allows for faster production rates and less labor-intensive handling.

Environmental Impact of Ecoating Technologies

The ecoating process is not only practical but also aligns with modern environmental standards and expectations. By using water-based paints and minimizing the emission of volatile organic compounds (VOCs), ecoating significantly reduces its impact on air and water quality. This is crucial in a time when regulatory factors are becoming increasingly stringent.

Additionally, many ecoating processes recycle rinse water and utilize efficient filtration systems, further minimizing waste. Overall, by adopting ecoating technologies, manufacturers in the West Midlands contribute positively to sustainability initiatives while maintaining high productivity.

Key Players in the West Midlands Ecoating Industry

Leading Ecoating Providers

The West Midlands hosts a variety of companies specializing in ecoating services, each offering different levels of expertise and technologies. Leading providers include:

- Plastic Coatings Limited: Specialists in electrophoretic painting, they enhance protection for components across various industries.

- Malcolm’s ACP: Focuses on surface coatings, including ecoating and powder coating, known for their high-quality finishes and reliability.

- East Midlands Coatings: Offering competitive pricing for electrocoating with an emphasis on corrosion protection services.

Comparative Analysis of Local Services

When selecting an ecoating provider, businesses should conduct a comparative analysis of the services offered. Key considerations include:

- Specialization: Different companies may specialize in various types of ecoating (e.g., automotive, industrial), affecting their expertise.

- Technology Used: Explore the technologies used by local providers; advanced methods may yield better results.

- Customer Feedback: Consider reviews and testimonials from previous clients to gauge reliability and quality.

Client Testimonials and Case Studies

Client feedback can be invaluable in assessing the capabilities of ecoating providers. For instance, a case study involving an automotive manufacturer in the West Midlands may highlight improved paint adhesion and reduced corrosion rates achieved through a strategic partnership with a local ecoating firm. Specific metrics reflecting the improvements, such as a 30% decrease in corrosion-related failures, can further substantiate the value of ecoating services.

Ecoating Process Explained

Step-by-Step Overview of Ecoating

The ecoating process is methodical and includes several key steps:

- Cleaning: Substrates are thoroughly cleaned to eliminate any grease, dirt, or oxidation.

- Pre-Treatment: A chemical pre-treatment may be applied to improve the adhesion of the coating.

- Coating: The component is submerged in an electrocoating bath, with direct current applied to facilitate a uniform layer of paint.

- Rinsing: Following the coating, excess paint is rinsed off to prevent pooling.

- Curing: Finally, the coated part is cured in an oven to ensure the paint adheres and achieves optimal durability.

Choosing the Right Ecoating Method

Choosing an appropriate ecoating method hinges on several factors, including:

- Material Type: Different materials may require specific coating technologies for optimal results.

- Desired Finish: Consideration of whether a matte or glossy finish is preferable can influence the choice of materials.

- Industry Standards: Adhering to industry-specific regulations may dictate the choice of coatings and methods.

Maintenance and Quality Assurance in Ecoating

Regular maintenance of equipment and a robust quality assurance program are both essential in ensuring that ecoating processes yield reliable results. This includes:

- Routine Equipment Checks: Regular inspections can help in identifying any potential malfunctions.

- Quality Control Tests: Implementing systematic quality checks during production can prevent defects.

- Feedback Mechanisms: Establishing channels for employee and customer feedback can lead to continuous improvements.

Applications of Ecoating Across Industries

Automotive Applications of Ecoating

In the automotive sector, ecoating is indispensable. It serves to protect vehicle components that are often exposed to harsh conditions, ensuring longevity and reliability. Components such as chassis, wheel rims, and engine parts benefit greatly from this process, with manufacturers noting improved performance and a reduction in materials replacement costs.

Electrocoating for Industrial Equipment

Beyond automotive applications, electrocoating is increasingly being employed in various industrial equipment sectors, such as construction and agriculture. The resilient coating helps to protect machinery from wear and tear, which leads to prolonged equipment life and reduced maintenance needs.

Emerging Trends in Ecoating

The ecoating industry is experiencing a wave of innovation. Trends include:

- Advancements in Eco-friendly Coatings: The development of bio-based materials is providing greener options without compromising performance.

- Increased Automation: Automation in the ecoating process is enhancing speed and efficiency, allowing manufacturers to scale operations.

- Customization of Coatings: The ability to customize coatings for specific applications is becoming more prevalent, tailored to industry needs.

Getting Started with Ecoating Services in the West Midlands

How to Select an Ecoating Partner

Selecting the right ecoating partner involves due diligence. Prospective clients should evaluate providers based on their industry experience, technological capabilities, and client feedback. Establishing clear communication can also enhance the partnership, ensuring that expectations are aligned.

Cost Considerations for Ecoating Services

Understanding the cost structure associated with ecoating services is crucial for budgeting. Factors influencing costs typically include:

- Volume of Work: Higher quantities often qualify for discounted rates.

- Complexity of Parts: More intricate designs may require additional setup time and care, affecting price.

- Additional Services: Pre-treatment and post-coating services can add to the total cost.

Contacting Ecoating Experts in Your Area

Engagement with ecoating experts can provide further insights into specific requirements and available services. Companies can reach out to local providers or consult industry associations for recommendations, ensuring that they receive tailored advice suited to their unique challenges.